Crane Time: Reliability as a Control Variable in Heavy Lift Operations

Three Pillars of Reliable Crane Operations

In crane operations, reliability is not a marketing slogan. It is a measurable outcome shaped by discipline, engineering standards, and proactive maintenance. At SMCLR, we treat reliability as a controlled variable, not a statistical afterthought. This edition of Crane Time examines three pillars of our operational model: excellence under load, subcontractor compliance, and reliability curve extension.

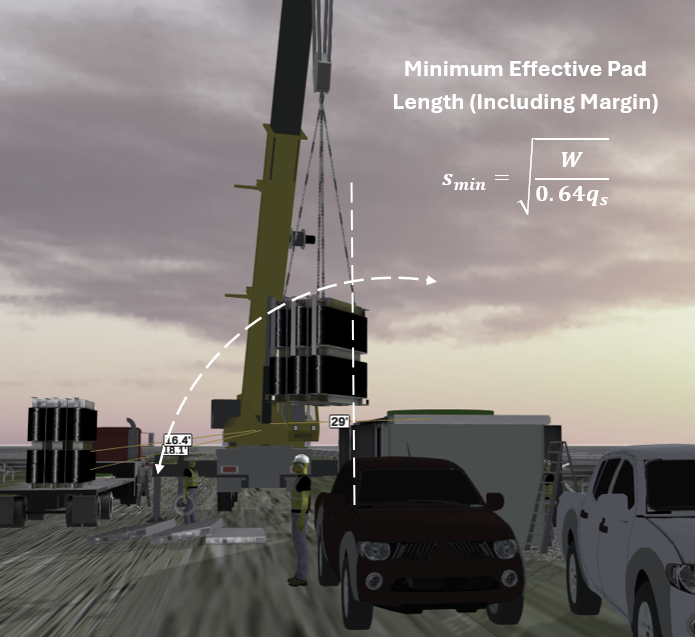

Excellence Under Load

In heavy lift operations every parameter such as boom angle, radius, and percentage of chart capacity functions as a control variable. SMCLR enforces preventive maintenance and load validation prior to mobilization, which eliminates uncertainty during execution.

By exceeding ANSI B30 thresholds and OSHA and DOT requirements, our operators maintain variance below 2 percent across extended campaign schedules. The result is predictable uptime, documented accountability, and operational reliability at scale.

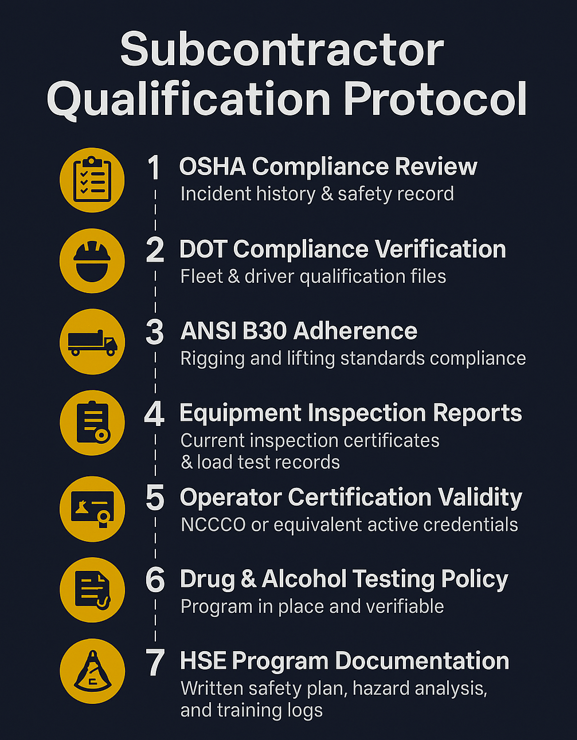

Subcontractor Compliance as a Lattice

Subcontractor qualification at SMCLR is not reduced to a convenience checklist. It is a structured verification process spanning twenty five parameters grouped into seven domains, each designed to ensure safety, reliability, and operational discipline before a subcontractor ever steps onto the jobsite.

Each domain is evidence-based, not self-attested. Qualification requires verifiable records: incident logs, inspection certificates, operator licenses, and written HSE programs. This removes ambiguity and eliminates subcontractors who rely on paper compliance without demonstrable performance. By requiring proof across multiple dimensions, SMCLR establishes a baseline where only documented reliability qualifies as operational reliability.

This lattice ensures that every subcontractor working under SMCLR enters the field with the same standards of safety reliability and operational discipline. The result is consistent uptime and zero tolerance for coordination gaps across projects.

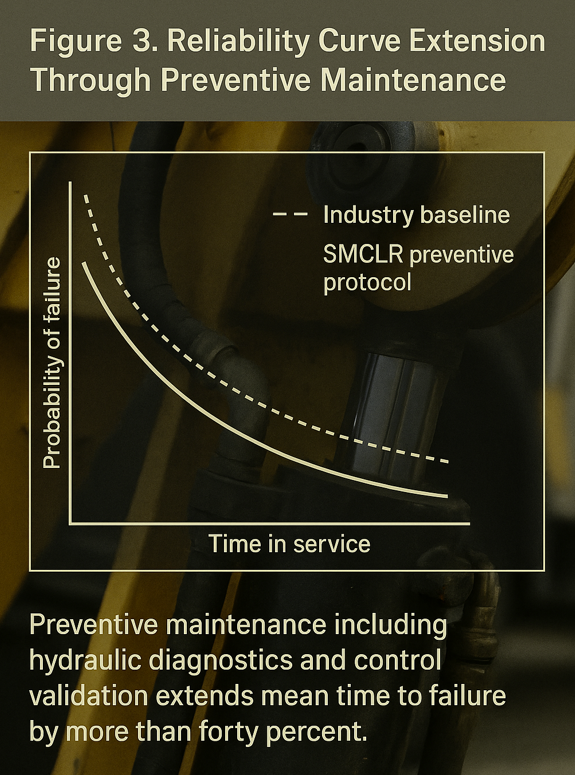

Reliability Curve Extension Through Preventive Maintenance

Reliability in heavy lift operations is determined by preventive action rather than reactive repair. Industry baseline practices permit failure probability to rise steeply as service time increases. SMCLR applies hydraulic diagnostics control validation and early component replacement to slow the progression of risk.

The resulting reliability curve extends mean time to failure by more than forty percent. This extension provides predictable uptime, reduces operational variance, and secures the execution of complex utility scale lifts.

References

- American National Standards Institute. ANSI B30 Standards on Cranes and Related Equipment.

- Occupational Safety and Health Administration. CFR 1926 Subpart CC – Cranes and Derricks in Construction.

- U.S. Department of Transportation. Federal Motor Carrier Safety Regulations.

For extended analysis on reliability economics in crane operations, read additional issues of Crane Time or contact SMCLR, A Crane Co. for peer reviewed project execution strategies.

Leave a Comment